Machine Dimensions

29”X 41”X 69”H

Max Tray Dimensions

15”X 11”

4-Up Max Output Capability

1-up: 240 pcs/hour

(skin seal 180 pcs/hour)

2-up: 480 pcs/hour

(skin seal 360 pcs/hour)

4-up: 960 pcs/hour

(skin seal 720 pcs/hour)

Electrical Requirements

220 Volt, 3 Phase

Power Consumption

10amps

Compressed air requirements

5HP Compressor

600KPa, 400-600L/Min, 80 psig

Inert Gas Requirement

80 psig and 5 scfm

Oxygen Residual Capability

0.5%-2% on solid product

Inert Gases

Nitrogen, Carbon Dioxide, Noble Gases

Net Weight

1100 lbs

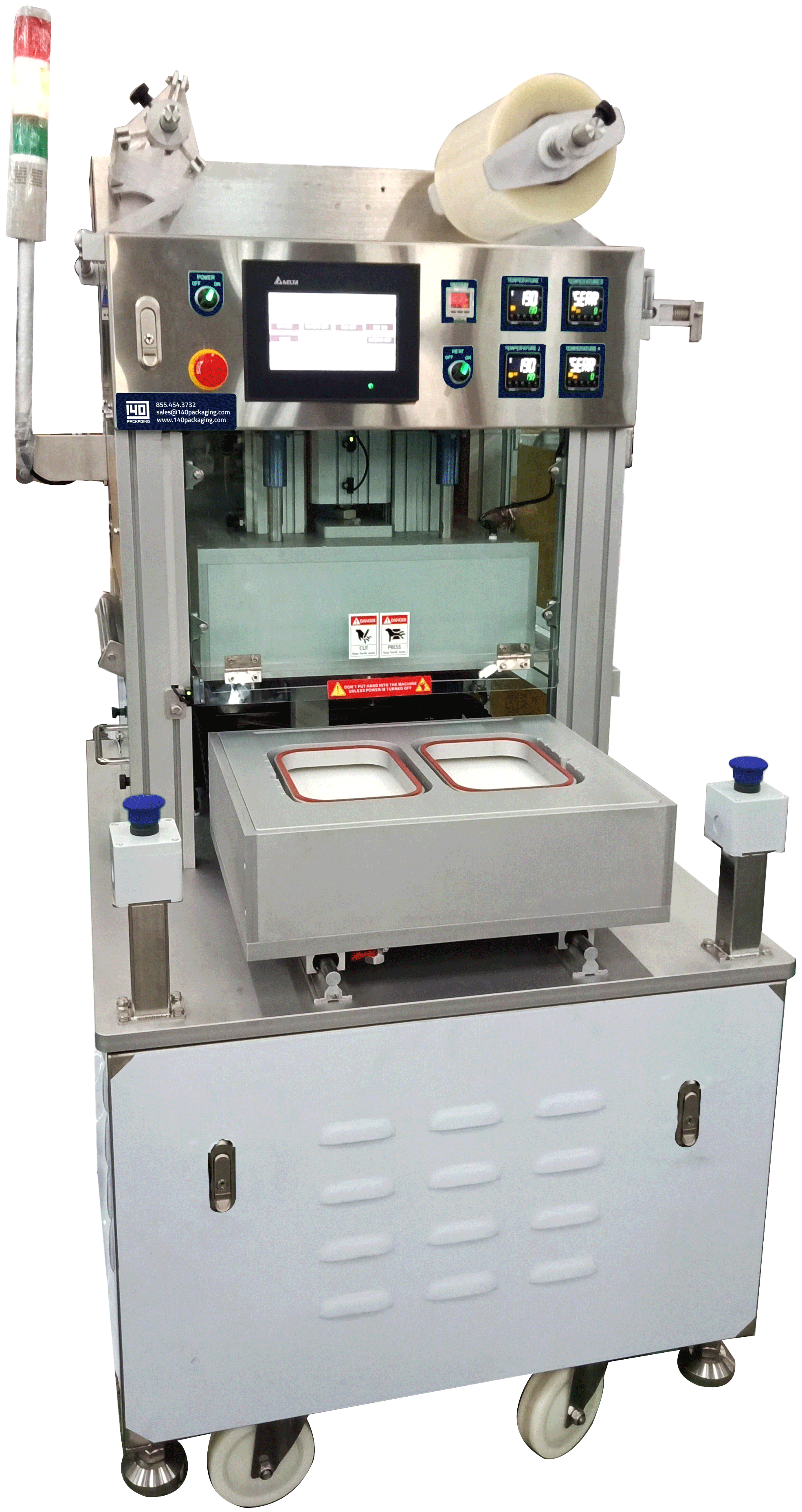

Our versatile floor model vacuum gas flush shuttle heat seal machine offers MAP and skin seal capabilities. This machine has easily interchangeable tooling and a built-in die cutter that automatically trims film to your container’s perimeter for an attractive presentation. The machine is extremely versatile as it can be set to either gas flush, vacuum gas flush, or skin seal packaging modes of operation. These programmable features and technology interact to substantially increase the shelf life of your product and ensure packaging meets your high standards.